What are the differences? While each wall may look similar from the untrained eye, each type of retaining wall varies in the process of construction and installation, as well as purpose and benefits. Three main purposes of retaining walls include:

- Safety: to prevent soil collapse or erosion into roadways, railways, residential or commercial property. Retaining walls can also temporarily provide safety on a construction site to keep the workers and excavation site from collapsing in or prevent water from entering the site.

- Sound: Sound barrier walls are designed according to the decibel levels of surrounding industrial, commercial or traffic sounds. The walls are proven to significantly reduce the noise pollution for neighboring communities.

- Aesthetics: The retaining walls are built not just for functionality but to provide a visually appealing solution to safety and sound. Often the walls are built with precast panels with a form liner stamp, which is an aesthetic treatment on concrete panels to achieve the look of natural stone. The panels and block walls are created and customized according to job specifications by a third-party vendor with a pattern or stone appearance requested by the client.

What type of wall is best in each situation? The type of retaining wall constructed depends on the variables in regard to location (including but not limited to: slope of the land, soil type, topography of land area, water tables and nearby waterways, proximity to roads and railways, and proximity to residential neighborhoods or pedestrian walkways). When all of these factors are considered, the engineering team determines the best type of retaining wall needed. These variables too decide the process of excavation, construction, installation, and the best methods to secure and retain the earth. In this article, we will define each type of wall, the various processes of construction, and the different needs they fulfill.

Retaining Walls:

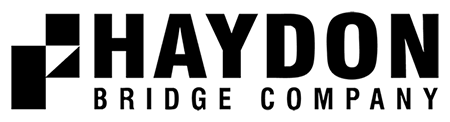

Retaining walls are rigid walls constructed to restrain soil on a slope that would not naturally keep, whether due to a steep slope, near-vertical slop or ninety-degree vertical slope. The walls prevent the earth or soil to collapse from either precipitation or erosion into areas of farming, residential properties, highways or roadway overpasses. Retaining walls are also built to retain earth from roads, waterways, parking lots, residential or commercial buildings, especially when there is not enough space to safely slope the soil. There are four types of retaining walls:

- Gravity Wall: Gravity walls depend on their mass (stone, concrete or other heavy material) to resist pressure from behind and may have a ‘batter’ setback to improve stability by leaning back toward the retained soil.

- Piling Wall: Sheet pile retaining walls are usually used in soft soil and tight spaces. Sheet pile walls are driven into the ground and are composed of a variety of material including steel, vinyl, aluminum, fiberglass or wood planks.

- Cantilever Wall: Cantilevered retaining walls are made from an internal stem of steel-reinforced, cast-in-place concrete or mortared masonry (often in the shape of an inverted T).

- Anchored Wall: An anchored retaining wall can be constructed in any of the aforementioned styles but also includes additional strength using cables or other stays anchored in the rock or soil behind it.

Processes of Construction of Retaining Walls

There are several types of construction processes to build a retaining wall, and they vary depending on the location, soil type, and the purpose of the wall.

- Rebar & Concrete Process: The walls are cast in place with concrete being poured, within a rebar frame and formed according to the needs of the land. This is the quickest construction process.

- Block Wall Process: Precast blocks are constructed by a third party and once the pad is excavated, the blocks are set and for each layer of blocks, the blocks are then backfilled with a granular material behind the blocks to promote positive drainage, and this process is repeated until the desired height is achieved.

- Bottom-Up Construction: The retaining wall frame and panels are placed once the full depth is excavated, and then the earth is backfilled to the top.

Retaining Wall Project on Reynolds Road, Lexington KY

Case Study: Haydon Bridge Company built a retaining wall on the railroad overpass of Reynolds Road in Lexington. Our engineers used precast panels with reinforcing beams to secure the wall panels. The precast concrete panels were stamped with the appearance of a natural stone wall for aesthetic purposes.

Soldier Pile Retaining Walls

Soldier pile walls are a form of embedded retaining wall that are used to retain the soil behind to allow the ground level in front of the wall to be lowered, the retained height can be increased with the use of propping or anchoring. A soldier pile wall can be a temporary structure in the case of protecting a construction site and supporting the earth during excavation, or permanently constructed to provide slope stabilization or a retaining solutions for cohesive soils/dense granular soils.

A permanent soldier pile wall can be constructed with a permanent concrete face and even a form-lined architectural finish in urban areas.

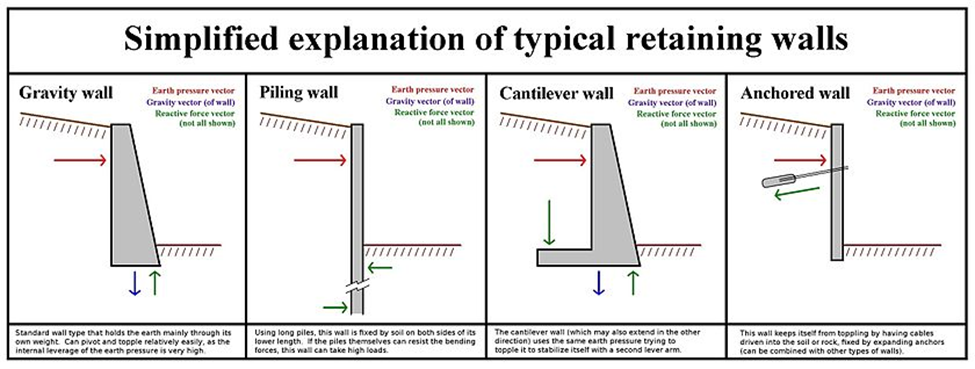

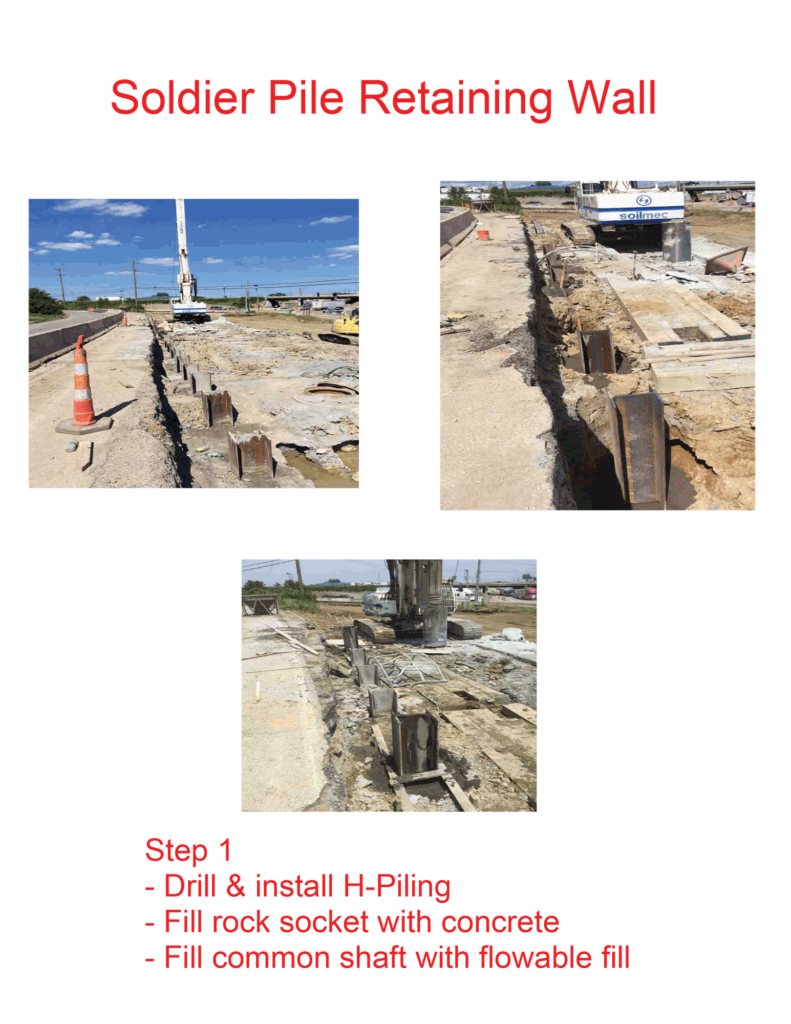

Process of Construction of Soldier Pile Walls:

- Top-Down Construction: The soldier pile is a method of top-down construction. The process begins with drilling holes for installing the soldier piles to the design depth. Once the required depth is cleared, the H-pile in place inside the hole, then filled concrete, flowable fill or granular material per the design. Once the piles are installed, excavation begins. As an example, a four feet section of earth is excavated, the timber lagging is inserted, then another four feet depth is excavated, with each time the beams are sliding down in between the H-pile. The reason only four feet is dug at a time is for safety reasons, to avoid collapse of the soil during the installation process. When building a retaining wall along a roadway, this top-down construction is necessary since excavation behind the wall becomes difficult with the lack of space next to the roadway.

- Soil Nail Wall Construction: A soil nail wall is another method of top down construction. The process begins with establishing a drill bench near the top of the wall. Then soil nails are drilled into the wall face, typically at a 10-15 degree angle down from horizontal, and grouted. This process continues along the wall until the top row is completed. Once a row of nails is completed, a temporary facing of steel mesh and shotcrete is applied to stabilize the soil. At this time, the drill bench is lowered, typically in 4’ increments, and the process is repeated. Once all of the soil nails and temporary facing is installed, a permanent facing of either shotcrete or concrete is installed for the full wall height. This permanent facing can be plain or have architectural treatment. *Soldier Pile retaining walls are built similar to cofferdams and sheet piling.

Sound Barrier Walls

A sound barrier wall is an exterior structure designed to protect inhabitants of sensitive land use areas from noise pollution. Noise barriers are the most effective method of mitigating roadway, railway, and industrial noise sources. These highway sound barrier walls are important to keep high traffic and highway noise from penetrating local neighborhoods and business districts.

Traditionally, these blockades use metal, brick, concrete or wood to minimize the loud noises generated by highway traffic. When needed, sound barrier walls can be constructed with environmentally durable composite construction that absorbs sound and blocks offensive noise. There is much discussion and debate over the materials used on sound barrier walls, because depending on the material, the noise can actually reverberate, increase and become higher in frequency when the concrete walls cause sound reflection.

A Sound Barrier wall is constructed with a drilled shaft foundation, where a rebar* cage is installed and concrete is poured with anchor bolts installed to provide the foundation for the posts. Subsequently, posts are set, then the precast panels are set between the posts. The precast panels are usually stamped with a faux stone wall appearance for aesthetic purposes since these walls are highly visible on both sides.

*Rebar (short for reinforcing bar), known when massed as reinforcing steel or reinforcement steel, is a steel bar used as a tension device in reinforced concrete and reinforced masonry structures to strengthen and aid the concrete under tension. Concrete is strong under compression, but has low tensile strength.

In Conclusion

When it comes to safety, quality, endurance and aesthetic-pleasing retaining walls, sound barriers and soldiered pile retaining walls, Haydon Bridge has over 50 years’ experience with a team of skilled engineering professionals. Our team will work closely with the client, local government, and engineering teams to best determine which type of wall is needed, as well as the process of installation, the materials needed, and the construction plans. We have dealt with multiple scenarios, various topographies of Kentucky and surrounding states, so we understand how to construct roadways, bridges and retaining walls that are built to last. Our company has a reputation, from day one to over 50 years later of being a highway and bridge construction company that produces quality work with high standards, honesty, integrity and efficiency without cutting corners.