2024 D9 Golf Scramble

Back in August, some of the guys competed in the 2024 KECC/KYTC District 9 Golf Scramble and finished in 2nd place! Everyone had a great time for a great cause! The team has already committed to working hard in the offseason to ensure a first place finish next year!

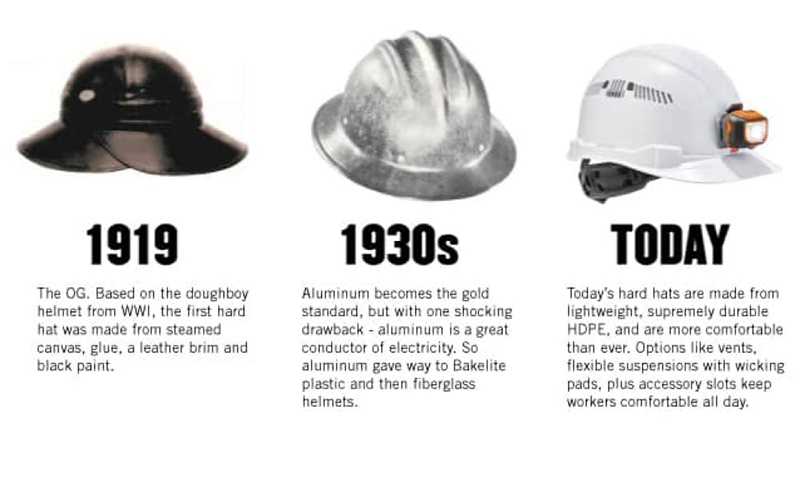

The History of the Hardhat

If you step foot on a Haydon Bridge jobsite, one of the first things you may notice is all the heads topped with a bright white hardhat adorned with the Haydon Bridge Logo. Despite what you might think, these hard hats are not ONLY worn to make us look good, but serve a very vital and functional purpose. The Haydon Bridge hardhat is one part of our minimum PPE (Personal Protective Equipment) Requirements, which must be worn on a Haydon Bridge Jobsite at all times. Despite the importance of this piece of PPE, many don’t know how we arrived at the modern day hardhat, so let’s take a look…

The first commercially available hardhat was called the Hard Boiled Hat and was made from Canvas and Leather. The concept arose after a U.S. Army Lieutenant witnessed the effectiveness of the helmet in a war setting and realized that it could be utilized in the postwar industrial environment as well. After the initial hat was developed, new versions with adaptations for different uses were soon created. At first, wearing a hardhat was a choice, not a requirement, and it remained that way until the construction of the Hoover Dam in 1931. During the construction of the dam, employers required workers to wear hard hats for the first time. Since then, the hard hat has gone through many evolutions and improvements to arrive in its current form. Take a look at the following article to get a more in depth look at the history of the hardhat:

Dan Holland

We would like to congratulate Dan Holland on his recent promotion to lead carpenter. Dan has put a lot of time and effort to make it to this point and continues to strive for more each day. Keep up the hard work Dan we appreciate everything you do for us!!

🚧 Wolfe County Culvert – Exciting Progress Alert! 🚧

Check out the transformation at our construction site! From an untouched landscape to a bustling hub of activity, our team has made incredible strides. The double barrel culvert is now complete, and backfilling is well underway. Swipe to see the journey from start to now!

#ConstructionJourney #ProgressInAction #BuildingTheFuture #InfrastructureDevelopment

Washington County Update

Since our last update on our bridge expansion on KY 555, we have been given the “All Clear” on our CSL testing report and have followed right in to column construction. To construct our columns, we use an efficient form system design by EFCO. We utilize a series of pipe braces to stabilize the column form and then drop our rebar cage into place. Once this is done, we drop in a hopper & chutes to help control the flow of concrete. We then use our crane combined with a concrete bucket to transport the concrete from the truck to the hopper chute and into the column form.